Our Product Development Process

Regardless of what stage of product development you are currently in, we can help solve any challenges you might be facing to bring your product to a level that you’re satisfied with.

Sketch

Once your idea has been conceived, you’ll want to know what you want it to look like. Our designers develop concepts by laying pen to paper. These sketches provide a general idea of what your product might look like and what design language will suit it best. We provide several iterations to choose from moving forward.

2D Illustration

Once you’ve selected a concept to move forward with, that concept is illustrated into a full-color illustration with textures giving you a sense of the product’s size, shape, and overall aesthetic. Here we can determine the design language that best suits your product.

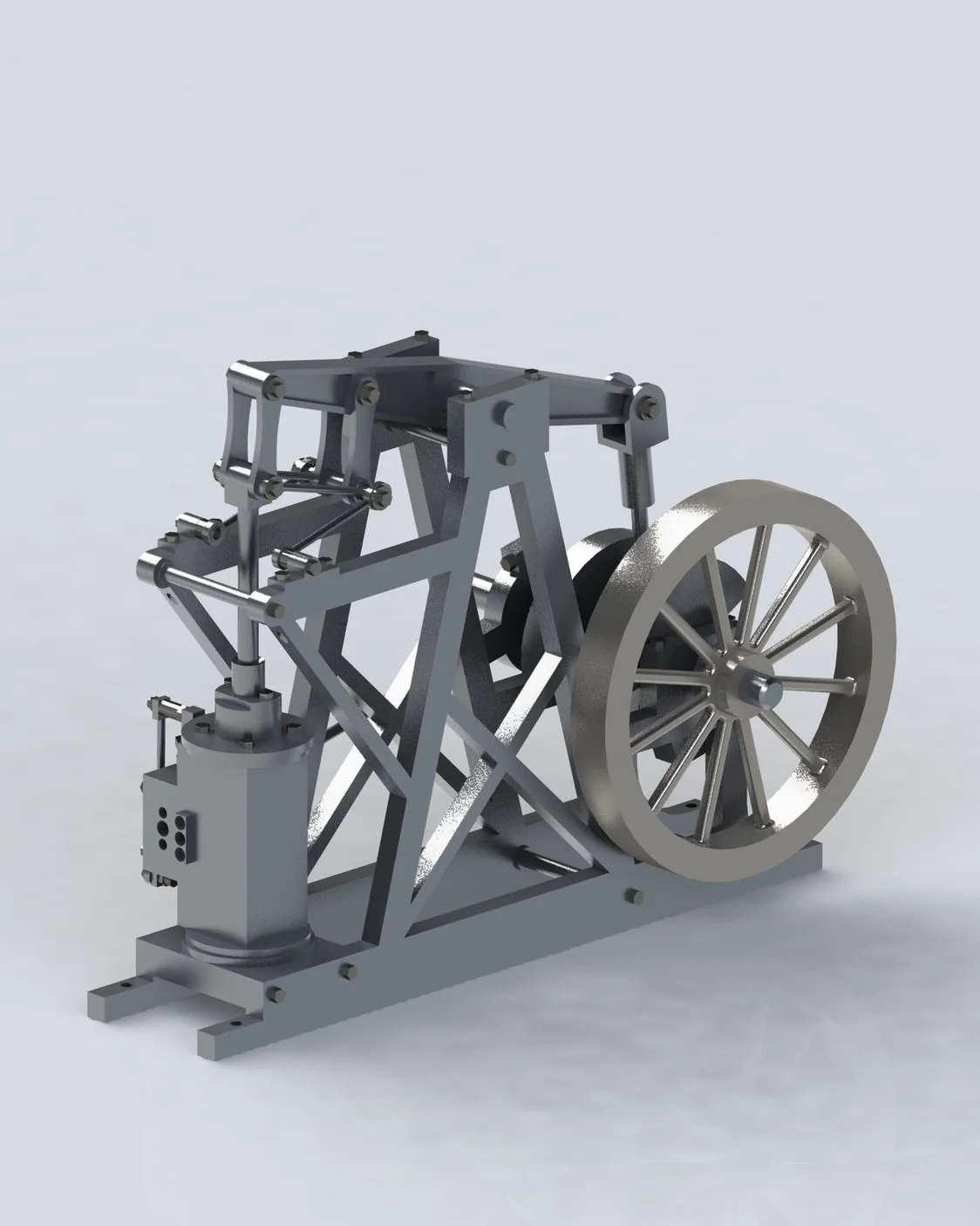

3D Model

From the illustration, our engineers develop a 3D model bringing your product to life. This model will serve as a reference for the overall aesthetic of your product as well a platform for any further engineering and production. It will continue to evolve alongside your product into the final stages of prototyping and is finalized once your product is ready for production.

Engineering

Once you’ve approved the design, we move forward and begin engineering your product. This means selecting the appropriate materials and components for your customers. Then, we begin to optimize your product by minimizing cost and maximizing value to the consumer while still retaining full durability and functionality. Once all the major issues have been addressed, prototype production can begin.

Prototyping

With an approved prototype design in place, we can begin prototype production using methods best suited to your design. From plastics to compounds to metals, we can use 3D printing, custom machining, casting, or some combination of the three methods to manufacture your prototype. Prototype manufacturing usually takes about _ weeks from an approved design to finished prototype. The finished prototype puts a physical product in your hands and will help us identify issues, concerns, and smaller details that could not be addressed throughout the design process.

Production

Once everything with the prototype has been perfected, your product is finally ready for production. Based on your budget and volume, we design and source a manufacturing process that is optimal for your product. Samples will be made to qualify the supplier’s process and quality. Since our experience encompasses raw materials, manufacturing, finishing, and assembly, we draw on our wealth of experience to design and source the most appropriate, cost effective, efficient process for your product.